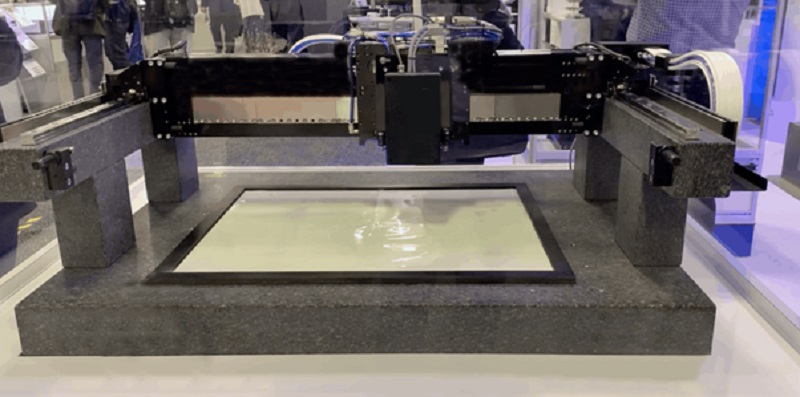

A gantry system is a large, movable arm that helps automate the manufacturing process. The gantry systems move along two rails, which guide it in the X and Y directions. This allows the system to easily and quickly transport products from one station to another.

Gantry systems are a type of overhead crane used to move heavy objects from one place to another. They are commonly found in factories and other industrial settings. There are plenty of benefits that come with using gantry systems, including:

Gantry systems can move objects much more quickly than traditional cranes. This can lead to increased efficiency in the workplace.

Moreover, they can handle much more weight than traditional cranes. This makes them ideal for moving large objects around a factory or other industrial setting.

They are best for larger loads.

The Gantry system is best for larger loads. They offer a stable and efficient way to move larger payloads from one point to another. The elevated support beam and movable cross members provide the versatility to position the load exactly where it needs to be. Additionally, the use of a gantry system allows for an ergonomic workspace, leading to increased productivity.

They provide adaptability and flexibility.

These systems are becoming an increasingly popular choice for large and small businesses due to their adaptability and flexibility. They can be used in a variety of ways to create an endless array of displays and signage, making them the perfect solution for any business that wants to stand out from the competition.

Also, they are straightforward to use and can be set up in minutes by anyone with basic knowledge of computers and software. This makes them the perfect choice for businesses that need a quick and easy signage solution without sacrificing quality or style.

They provide maintenance

Meticulously, these systems provide maintenance, service and installation of overhead cranes, gantry cranes, jib cranes and other material handling equipment. We have experience with most cranes and can offer a solution for your needs.

Our highly skilled technicians provide service and support for all types of cranes and material handling systems. We also offer preventative maintenance programs to keep your equipment running at peak performance.

They use V Guide Technology.

Gantry systems use V Guide Technology to achieve high speed, precision and accuracy. They are used extensively in the automotive and aerospace industries to manufacture a wide range of products.

The basic principle behind a gantry system is that the two axes of motion are perpendicular. This makes it possible to move the workpiece in two directions at once, which leads to much higher speeds and throughputs than can be achieved with a traditional XYZ table.

The use of V Guide Technology ensures that the motion of the gantry system is always perfectly aligned with the workpiece.

They provide integration

Gantry systems provide integration between the front-end and back-end of a website, allowing developers to create visually appealing and functionally sound templates. In addition to their importance in web design, gantry systems also provide many other benefits.

One of the main advantages of using a gantry system is that it enables developers to create templates that can be reused across multiple websites. This saves time and effort and ensures that all sites have a consistent look and feel. Additionally, gantry systems make it easy to update or modify designs, making them an excellent choice for businesses.

They are efficient

A Gantry system is efficient and perfect for a production line. They are perfect for products that are the same size and shape. The products are placed on a conveyor belt and go through the machine. Different gantry systems can be used for various applications.

Some gantry systems have a welding head and a cutting head. The welding head welds the product to the correct shape, and the cutting head cuts off the excess material. Other gantry systems have a spraying head and a curing head.