Choosing the right industrial steel caster wheels requires you to consider a few things before deciding. These things include the Wheel diameter, Cost, Ergonomic considerations, and the Axle shaft/axle bearing.

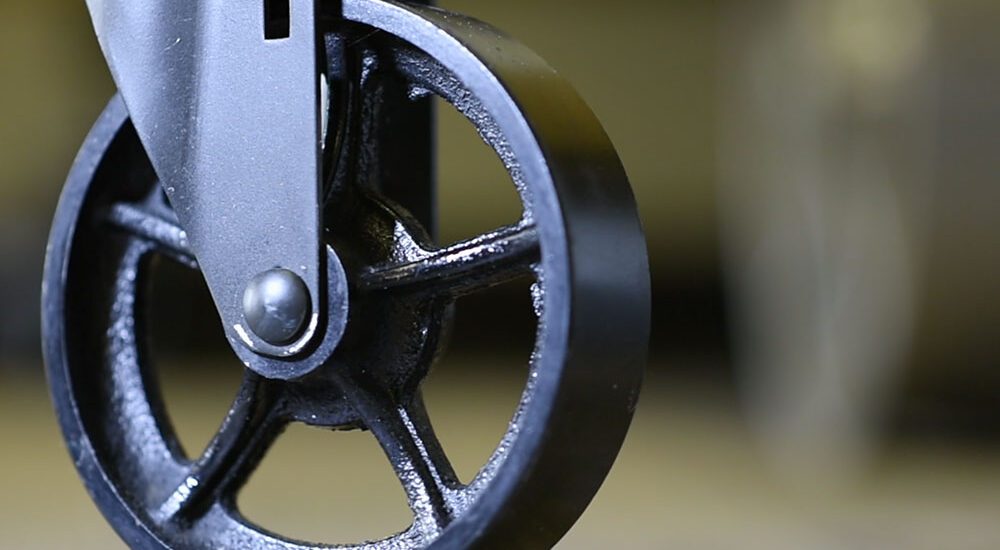

Axle shaft/axle bearing

Choosing the correct axle shaft/axle bearing for your industrial steel caster wheels can be confusing. There are several choices available, and knowing the product name is essential.

For high-speed applications, a tapered roller bearing is a suitable option. These bearings can support more weight than ball bearings since the race is toughened. Additionally, they last longer in service.

For a more cost-effective bearing, the straightforward approach is a good choice. This bearing uses a hub material, which is pressed into the wheel. The most significant race that contacts the bore is the outer race.

The best bearing for heavy loads is a tapered roller bearing. This bearing has a hardened outer race and a smaller one that rides in the inner one. It can also absorb excessive friction when a load tips.

The non-round tee-head is machined into the face of the left hub. It is matched with the adjacent non-round hex shape on the right tip of the axle. These create a non-rotatable connection when the axle shaft is mated with the axle.

Wheel diameter

Choosing the right wheel diameter is crucial for heavy-duty industrial steel caster wheels. The incorrect size will result in an uncomfortable fit and challenging duty. These wheels are made to be solid and reliable. They are suitable for applications involving shock and harsh environments.

Maximum impact strength and resistance to high temperatures are features of forged steel wheels. They can also endure grease and oils. These wheels may be applied to smooth concrete or steel surfaces. They come in a variety of finishes as well. They may have roller bearings or Teflon bearings installed. Additionally, they can be employed in aggressive chemical or greasy situations.

Polyurethane wheels are durable, easy to roll, and resistant to shock and chemicals. They are suitable for institutional applications. They can handle storage loads without going flat or leaving any marks. They also have excellent abrasion resistance. They are handy for industrial applications where a shock is not a concern.

Ergonomic considerations

Investing in ergonomic caster wheels can be a good business decision. It can help keep your employees safe and improve productivity.

Ergonomics is a field focused on design and how things are arranged. For example, ergonomic considerations can be applied to cart design and how an employee handles equipment.

Ergonomic considerations can include things like the size and materials of the wheels and the bearings used. The environment can also influence these factors. For example, if the job involves working in a chemical-filled climate, you should choose caster wheels resistant to chemicals.

Ergonomic considerations can also reduce injuries. For example, casters can reduce strain on your back and shoulder muscles by reducing the force needed to push or pull an object.

An ergonomic caster wheel is usually made of materials with lower rolling resistance. Therefore, it allows for easier maneuverability, especially when moving heavy loads.

Cost

Choosing the right wheel is essential for your material handling project. You can find casters in different shapes, materials, and sizes. Selecting the correct type of wheel will ensure maximum productivity.

The industrial steel caster wheels can be used for hauling heavy loads. They are designed to hold loads up to 20,000 pounds each. They can also be used in applications exposed to harsh service conditions. They can handle temperatures of up to 700deg F. This makes them ideal for applications such as food service.

They can also move materials in garbage bins or waste collection points. Choosing the correct wheel type will help lower your internal material handling costs.

Casters are one of the oldest tools used for material handling. They can be used for hauling loads. They are made from high-quality materials.

Some of the options available include steel, rubber, and polyurethane. Rubber casters are softer than polyurethane. As a result, they offer a more comfortable ride and are not prone to marks or shock. Polyurethane wheels are especially suited for institutional applications. They can handle storage loads, chemicals, and solvents. They are also easy to move on smooth floors. They are also able to run faster-operating speeds.